Vi 3 2000 has two straight arms with capacity to mount two moulds of 1000 liter or four 500 liter on each straight arm and one offset arm with capacity to.

Rotational molding machine specification.

Rotational molding machines rock and roll machine.

From our staple 3 x 4 and 6 x 6 machines to custom oversize and computerized units safety endurance and quality are our keywords.

Since 1987 mannetron has been building rotational casting machines to rigorous technical standards.

The molds rotate or tumble on separate axes at once.

Each arm rotates or rolls the mold 360 degrees.

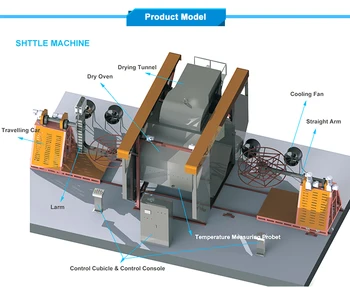

Some are of the clamshell type thus one arm but there are also shuttle type rock roll machines with two arms.

Cnc boring mills 2 cnc glass stone machines 1 cnc horizontal machining centers 37 cnc lathes 156 cnc routers 59 cnc vertical machining centers 114 cnc vertical turret lathes 7 edm 32 engine tool room lathes 6.

Specification sheet of rotational molding machines specifications vi 3 2000 machine vi 3 2000 is a bi axial machine with traveling furnace.

In rotational molding hollow molds filled with powdered plastic are secured to pipe like spokes that extend from a central hub.

Plastic rotational molding machine it involves rotational motion to effect the pressure needed to fill the mold to be a complete product.

This is a specialized machine designed mainly to produce long narrow parts.

The pallets are moved intermittently normally on a consistent time cycle to each machine station.

Rotational molding machine is ideal for making large hollow or concave shapes without high precision requirement often for outdoor use like children s slide.

Plastic rotational molding 12 thermo formers 36 machine tools.

Free non member price aud 30 plus tax if applies there are many different types of machinery in rotational moulding all requiring careful thought about managing the hazards and safety issues through appropriate risk management.

Batch machines formers dipping molds are mounted on pallets often as 1 2 meters by 2 4 meters.

Our in house machine shop and multiple rotational molding machine are all environmentally friendly producing minimal waste utilizing up to 100 recycled materials to customer specification.

The hub swings the entire mold into an enclosed furnace room that causes the powder to melt and stick to the insides of the tools.

For actual dipping stations the pallets move over the tank and the pallet is dipped into the tank or alternatively the tank is raised to the pallet of formers.

Constructed from a high density polyethylene pe plastic this solution is perfect for military shipping barrels outdoor equipment playground equipment.

Ideal for short and medium run projects our machines lead the market in durability and affordability.

Specification sheet of rotational molding machines 22 specifications en 2500 machine en 2500 is a single station bi axial rotational moulding machine with one u arm which has capacity to mount a mold of 2500 liter or 2000 liter or 1500 liter.